Biological Grease Traps

Basic characteristic

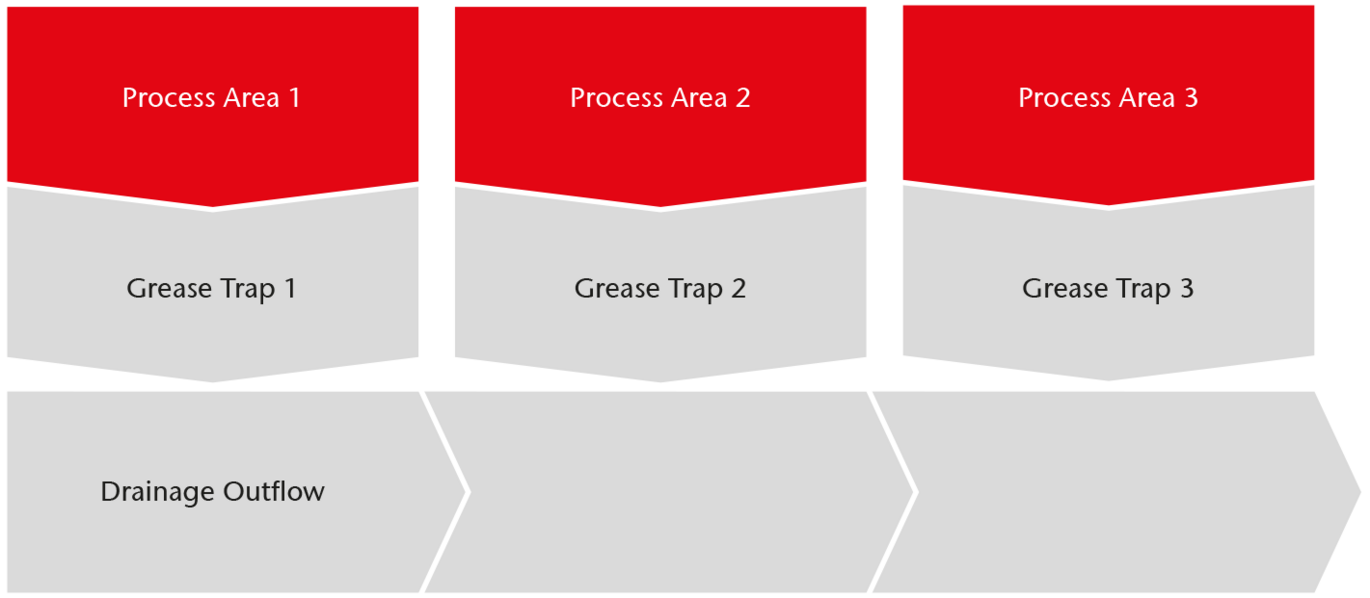

All ACO grease traps work on the same principle of gravity separation.

The mixture of contaminated water and fat, oil and grease (FOG) flows into the device by passing a sediment basket. The sediment basket removes any larger particles that may be present in the drain waste. It is important to note that the sediment basket volume is limited, therefore any significant amounts of debris should be removed before entering the grease trap or grease separator.

The physical capacity of the trap provides a separation area where relative density differences allow finer solids to settle to the trap floor and less dense FOG’s to rise to the surface.

Separation occurs relatively quickly, thereby allowing less contaminated water to flow to the outlet drain during periods of intense use.

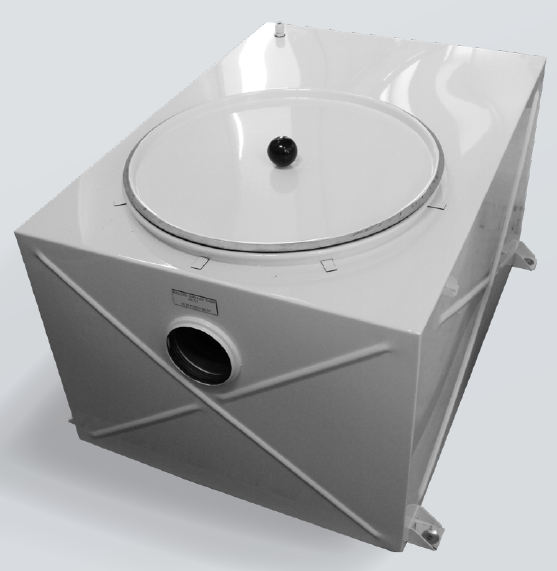

Grease Trap body material solutions:

- ACO Grease Trap - FSS Stainless Steel AISI 316L

- ACO Grease Trap - FSP Plastic PE-HD

Biological activators

Unlike strong acid or caustic drain cleaners, ACO biological activator works safely, but more slowly. The biological activator can be used to unblock drains and can be used to replace aggressive caustic and acid cleaners.

ACO biological activator works in two distinct ways on the FOG wastes that settle in the drainage pipework and grease trap system:

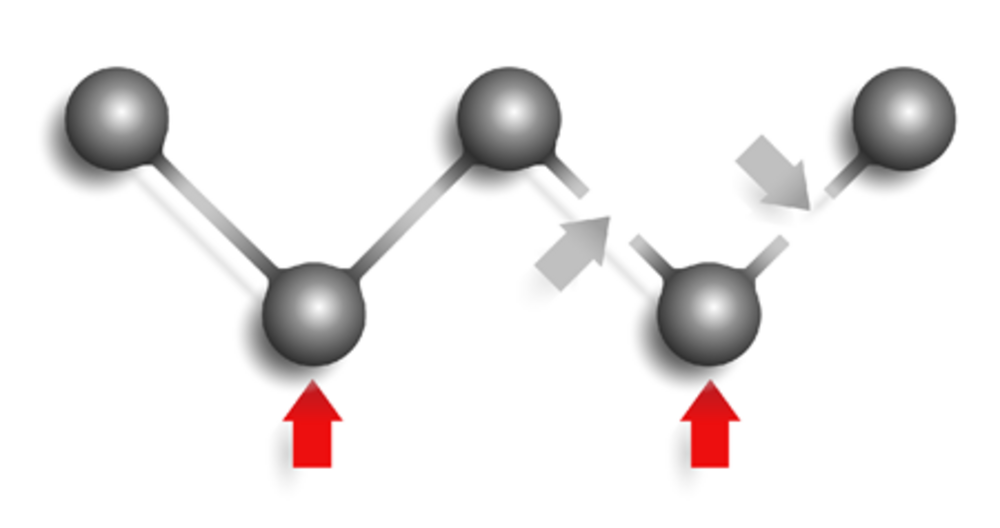

- The activator introduces an enzyme that assists the natural biological process of breaking down long molecular chain FOG’s into a manageable solution to then be discharged safely into the drainage system.

- The activator introduces other microorganisms that actively feed on the FOG’s present in the solution.

Biological activators will not digest solid residues from the food preparation process quickly, so the sediment basket requires periodic removal for cleaning to ensure efficient operation.

ACO Clear biological activator is available in 5 or 20 litre containers.