Grease Separator System

Basic characteristic

ACO Marine Grease Separators are proven products for Fats, Oil and Greases (FOG) removal from Galley water.

Galley water must first pass through a Grease Separator unit before entering any membrane wastewater treatmant plant as FOG's can have an averse effect on membrane performance and life expectancy.

Features

- Resistant to high temperatures

- Hygienic material stainless steel AISI 316L or PE-HD

- Rigid construction to withstand vessel movement and vibration

- Resistant to organic solvents

Operating Principles

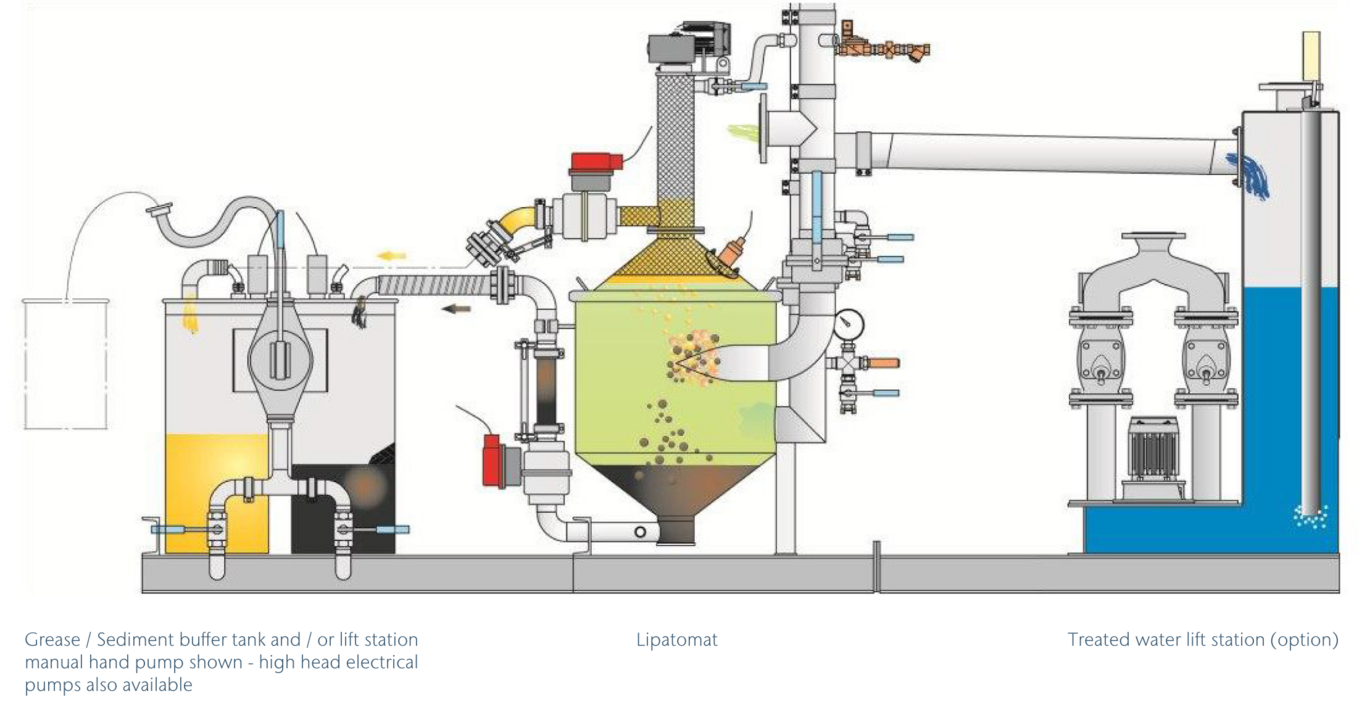

By locating the inlet and outlets slightly above the separation chamber the resulting small hydrostatic pressure makes Lipator and Lipatomat Grease Separators the only units of their kind whose separation efficiency is completely unaffected by vessels movement and vibration. The grease accumulates in the upper cone whilst the sediment drops to the lower cone. The heating element located in the upper cone ensures the grease remains liquid. Clean water passes freely and continuously through the grease separator.

Accumulated sediment and grease is drained to independent collecting barrels fitted with level sensors which provide indication to the operator when they need to be emptied or replaced with exchange units. Grease and Sediment lift pumps as well as treated water lift station, can also be integrated into the system depending on installation requirements aboard the vessel.