Push-fit Pipe System

ACO Marine's Push-fit Pipe System offers a highly efficient solution for managing the transfer of wastewater onboard ships, simplifying the process for both operators and crew. Whether it’s wastewater from kitchens, showers, laundry facilities, or other critical areas, this system is designed to handle it seamlessly, ensuring optimal performance in even the most challenging marine environments.

By streamlining wastewater management into a single, effective step, the Push-fit Pipe System significantly reduces the complexity associated with traditional systems, offering a straightforward and reliable solution for vessel drainage.

Built from high-quality stainless steel, the ACO Marine Push-fit Pipe System ensures long-term durability and resistance to corrosion, making it perfectly suited to the harsh conditions of the marine environment. The system is designed to operate efficiently in extreme temperatures, withstanding exposure to saltwater and other corrosive elements while maintaining peak performance. This durability not only guarantees a longer lifespan but also reduces the need for frequent replacements, providing a more sustainable and cost-effective solution over time.

Reliable safety and stability for seismic-resistant construction

ACO Pipe stainless steel pipework systems are manufactured from austenitic stainless steel in grades 1.4301 (AISI 304) and 1.4404 (AISI 316L). All products undergo chemical pickling and passivation to ensure optimal durability and corrosion resistance.

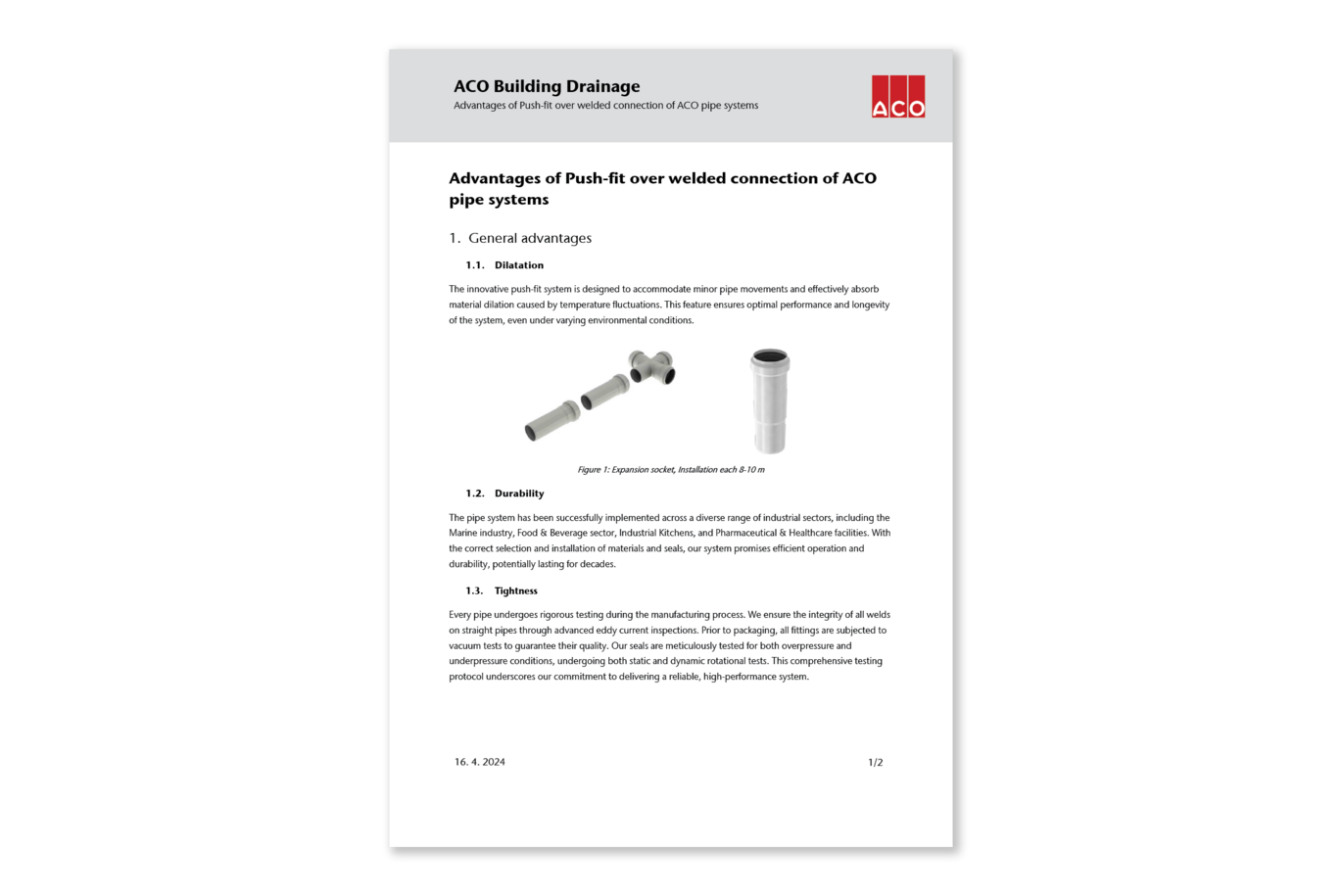

The innovative push-fit system is designed to accommodate minor pipe movements and effectively absorb material expansion caused by temperature fluctuations. This feature ensures optimal performance and longevity of the system, even in varying environmental conditions.

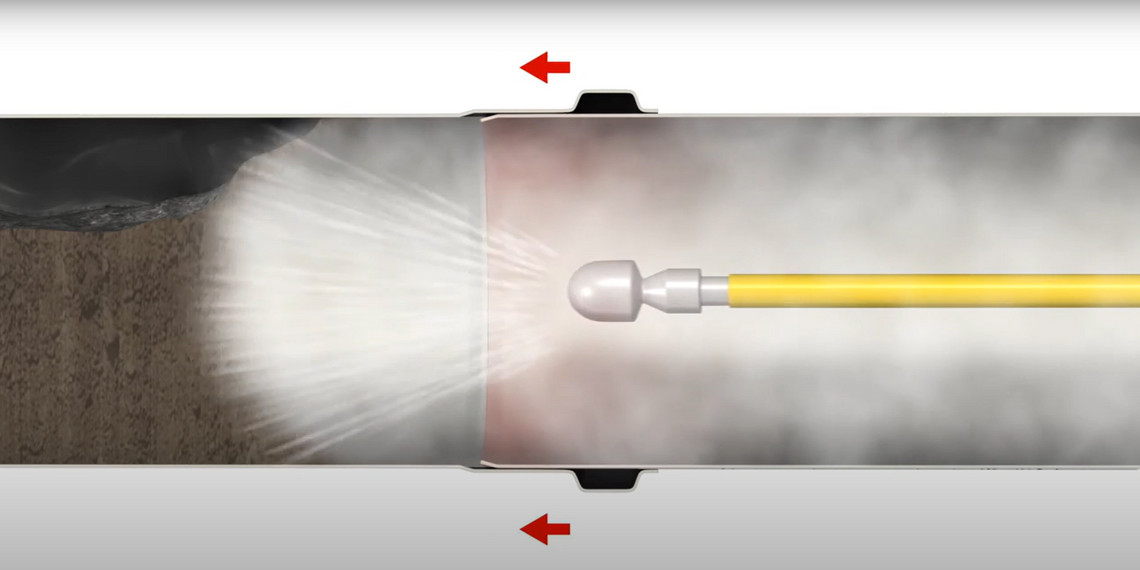

In many regions, stainless-steel pipework is commonly connected by welding, but this method poses risks in areas prone to tectonic activity. In 2015, ACO tests showed that push-fit pipes offer greater resilience to ground disturbances compared to welded joints. The system compensates for longitudinal and transverse movements through slight shifts within the socket, ensuring superior performance. These results demonstrate the system's ability to withstand underground movements and high tension. Tests confirmed that push-fit pipelines endure greater forces than welded ones, highlighting the durability and reliability of ACO's system.

ACO Pipe is classified and certified as a non-combustible product because it is manufactured in compliance with EN1124, Parts 1 & 2, which classifies the ACO Pipe system as Class A1 fire resistant. It requires no additional fire collars during installation and produces no toxic fumes in the event of a fire.

ACO Pipes are EPD (Environmental Product Declaration) certified, providing transparent and verified information about their environmental impact throughout their lifecycle. This certification confirms that ACO Pipes meet stringent sustainability criteria, from raw material extraction to manufacturing, use, and disposal. With EPD certification, ACO ensures its pipe systems contribute to sustainable construction, offering both high performance and eco-conscious solutions.

ACO pipe is...

Sagging-proof

- ACO pipe requires less fixing points than both plastic and Cast Iron.

- Plastic: due to the risk of pipe sagging, good fixing is critical in plastic pipes. Requiring more fixing points and more labour.

- Cast Iron: ACO pipe is much lighter when compared to cast Iron, making its fixation easier and quicker.

ACO Push-fit Pipe System

The ACO push-fit pipe system, made from stainless steel (available in AISI 304 and 316), offers a modern alternative to plastic and zinc-coated pipes for water drainage and vacuum systems.

The ACO push-fit pipe system boasts proven resistance to aggressive media. A diverse and versatile range of fittings is available, along with ACO drainage channels and scuppers, allowing for creation of a fully tailored pipe system solution. Its simple assembly and installation, combined with reduced installation time and exceptional corrosion resistance, make it a cost-efficient alternative to conventional flanged black steel systems.

The ACO push-fit pipe system is recognized and certified by all leading maritime classification societies.

ACO GM-X Galvanized Pipe System

The ACO Marine GM-X push fit pipe system is crafted from galvanized carbon steel and features an additional internal coating to protect against abrasion and reduce the risk of damage to the galvanic coating.

The GM-X system is designed for use with a wide range of ACO fittings, drainage channels, and scuppers, enabling the creation of a fully tailored pipe system solution. Its simple assembly and installation, along with reduced installation time, offer a cost-efficient alternative to conventional flanged system.

Advanced ACO production technologies and in-house galvanizing plant at our dedicated facility in the Czech Republic ensure consistent quality control throughout the entire production process.