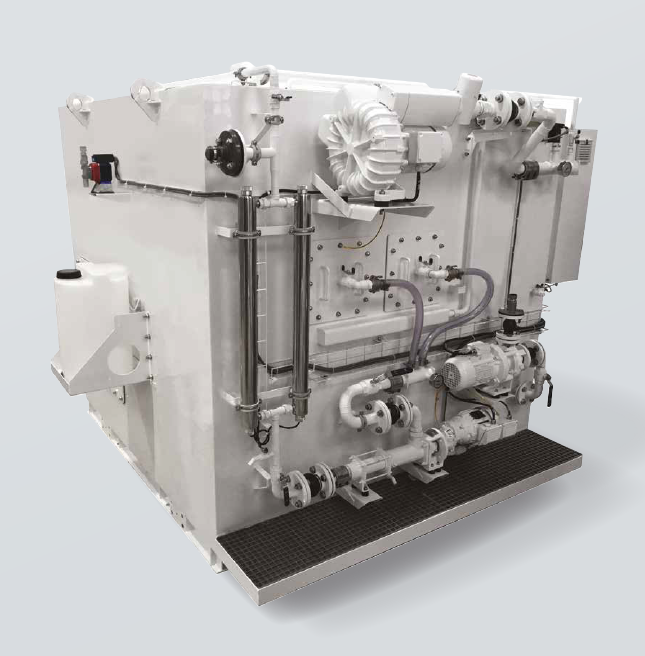

The ACO Clarimar MF biological sewage treatment plant incorporates ACO-MF filtration technology eliminating the requirement for settling and chlorination stages. Disinfection of the treated effluent is by in-line mounted UV lamp with no requirement for chemicals in any part of the ACO MF process.

The unique properties of the ACO ‘bio-sword’ allow operation with bio-mass concentrations in the activation chamber up to four times higher than those of conventional settling type sewage treatment plants. By operating at such high concentrations, a greatly reduced activation tank volume is achieved with a significant reduction in both the footprint and maintenance envelope requirement.

- Type Approved to IMO MEPC 159(55) and MED Module B

- Type Approved to IMO MEPC 227(64) and EC MED Module ‘B’

- Life–time corrosion guarantee² on tank material

- Compatible with both gravity and vacuum systems

- Self-cleaning ‘Bio-Sword’ with ACO-MF filtration technology dramatically exceeds all IMO requirements

- Manufactured entirely in the EU from high performance materials which, unlike coated black steel, are completely corrosion resistant and light weight

- Modular design concept for simple installation requiring only one power connection

- Lowest running costs of any sewage treatment plant on the market with minimal operator intervention

- Unaffected by ship movement or vibration

The main tank is manufactured entirely within the EU from high performance ‘ACO Composite PPFR GREY’ material which, unlike coated black steel, is light weight and completely resistant to corrosion, abrasion and chemical attack. Available as standard in grey colour.

The tank is supplied as a complete welded construction directly mounted on to a primer painted steel baseplate (sizes MF-6 and above) for direct welding or bolting to the ship structure. Smaller units up to size MF-4 have no baseplate and mount direct by bolting (using pre-drilled holes in the extended tank base) to the ship’s structure.

Where fitted, the baseplate includes openings for manipulation with fork lift. Lifting eyes are positioned at each tank upper corner for manipulation by crane.

All other components are also mounted on the base frame providing a complete ‘plug & play’ installation solution. All Clarimar MF installed components are designed to operate, as standard, in the voltage range 380 to 440 volts and at frequencies of either 50 or 60 Hz, without any additional modification. Additional voltage options are also available

Control of the system is via an IP55 rated steel cabinet complete with safety isolator and volt-free contacts for connection to the ship’s central monitoring and alarm system.